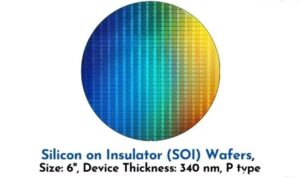

1- Bonded SOI wafer (绝缘硅上键合硅片)

|

For 4”(100mm), 5”(125mm), 6”(150mm)

—— Handle wafer minimum 300um maximum 1000um

—— Buried Oxide, minimum 0.1 um, maximum 4 um

—— Device layer minimum 2 um, max 500 um.(几十至几百纳米for6英寸)

|

For 8″(200mm)

—— Handle thickness minimum 500um and maximum 675um,

—— Buried Oxide minimum 0.1 um, maximum 4 um

—— Device layer minimum 5 um, maximum 500 um(几十至几百纳米)

|

2- Si-Si direct wafer bonding (replacement for epi) 硅–硅直接键合,可替代外延片

100mm, 125mm, 150mm and 200mm, thickness as specified above.

|

3- Engineered SOI, Double SOI (DSOI), Trench Isolation SOI (dielectric isolation),

Cavity SOI (for pressure sensor, gyro and accelerometer sensor, microfludic etc.) and finally Through Silicon Via (TSV)

—— Cavity SOI- Bonded SOI or Silicon DWB wafers with cavities performed within the wafer

—— Multiple SOI 2 or 3 or more layers of SOI designed around your process

—— Structured wafers silicon wafers or SOI with buried electrode layers, vias, interconnect already incorporated

|

4- SOI + Trench & Refill Features

a. Significant die shrink compared to conventional dielectric isolation(DI) or junction isolation

b. Bulk quality top silicon layer

c. Total device-to-device isolation

d. Lower substrate capacitance than bulk

e. Fully flexible specification on SOI, Trench and refill parameters

|

5- Superjunction MOSFET

|

Parameter Parameter

|

Specification Range

|

Wafer Diameter

|

100, 125, 150 mm

|

200 mm

|

Handle Layer Specifications

|

Handle Thickness

|

200–1000 µm

|

500-750 µm

|

Handle Thickness Tolerance

|

±5 µm

|

Stack Thickness

|

≥280 – ≤1250 µm

|

Dopant Type

|

N or P

|

Doping

|

N type: Phos, Red Phos, Sb & As

P type: Boron

|

Resistivity

|

≤0.001 – ≥10000 Ω-cm

|

Growth Method

|

CZ, MCZ or FZ

|

Crystal Orientation

|

<100>, <111> or <110>

|

Backside Finish

|

Lapped/Etched or Polished

|

Buried Oxide Specifications

|

Thermally Oxidised Buried Oxide Thickness

|

0.2 – 5.0 µm grown on Handle, Device or both wafers

|

|

Device Layer Specifications

|

Device Layer Thickness

|

≥1.5 µm

|

5-300 µm

|

Tolerance

|

± 0.5 µm

|

±0.8 µm

|

Dopant Type

|

N or P

|

Doping

|

N type: Phos, Red Phos, Sb & As

P type: Boron

|

Resistivity

|

≤0.001 – ≥10000 Ω-cm

|

Growth Method

|

CZ, MCZ or FZ

|

Crystal Orientation

|

<100>, <111> or <110>

|

Buried Layer Implant

|

N type or P type

|

SOI应用优势

|

SOI高速特性

|

微处理器,高速通信,三维图象处理,先进多媒体

|

SOI低压低功耗特点

|

移动计算机,移动电话,便携式电子设备,射频集成灵巧功率器件以及其它要求功耗低、散热快的领域,如单芯片系统SOC,微小卫星等

|

SOI应用于恶劣环境

|

高温器件,高压器件,卫星或其它空间应用,武器控制系统等

|

SOI光通信和MEMS应用

|

作为一种结构材料,可制作硅基集成光电器件,应用于高速宽带互联网和其它光网络的接口。此外,SOI圆片还广泛应用于制作微机电系统(MEMS)器件,如传感器

碳化硅sic衬底 优质晶圆厂家 硅片哪里能买到 |